Shed air conditioning allows the air to circulate properly. This makes the environment more pleasant for the performance of activities, avoiding dryness in the airways of employees and helping to combat fungi and bacteria in the air. Therefore, it is essential to know the best solutions for the acclimatization of warehouses.

There are several options available in the market, from mechanical climatization systems to more sustainable solutions, such as natural ventilation. The choice of the best solution takes into account the size of the shed, the type of activity that will be developed and the region in which the shed is located.

Next, we will detail the importance of air conditioning in warehouses and present the best solutions in this context, highlighting the advantages of each one. Confi

The importance of acclimatization in warehouses

The climatization of warehouses is extremely important to maintain a suitable environment for the activities performed inside them and to ensure the well-being and productivity of employees working there. Understand better!

More sustainable

The most indicated ventilation projects of air conditioners for sheds act as a continuous air renewal system, and the great advantage is that they do not depend on energy sources to function.

Thus, they are in line with the most modern demands of associating air conditioning with more sustainable mechanisms. This generates savings and well-being, and positions the industry in question as a sustainable brand in the market.

Lower equipment maintenance costs

Many equipment used in industrial warehouses are sensitive to temperature and humidity and can suffer damage or reduced service life if not kept in proper conditions.

Thus, proper air conditioning can help reduce costs with frequent maintenance of this equipment.

Energy Savings

Correct climate control in warehouses can reduce energy consumption and increase energy efficiency.

A well-designed and sized HVAC system can use less energy to maintain ideal temperature, humidity, and ventilation conditions, reducing energy costs and contributing to the preservation of the environment.

Best air conditioning solutions to apply in warehouses

As mentioned, there are several HVAC solutions that can be applied in warehouses, and the choice is influenced by the characteristics of the site, the activities performed in the shed, and the region where it is located.

Check out, below, the main HVAC solutions to apply in warehouses.

Natural ventilation

Natural ventilation is a process of renewal and circulation of air in an environment without the use of mechanical equipment such as fans or air-conditioners.

It occurs through the inlet and outlet of air, taking advantage of pressure and temperature differences, as well as outside air currents. There are different ventilation design options. Check out the main ones!

Windows and doors

Here, we are talking about a simpler solution, which uses windows and openings to allow fresh air in and warm air out, a constant air exchange.

This solution is recommended for mild climate locations with installations that actually have air circulation. In the case of warm climates, this type of simple solution may not be a good option.

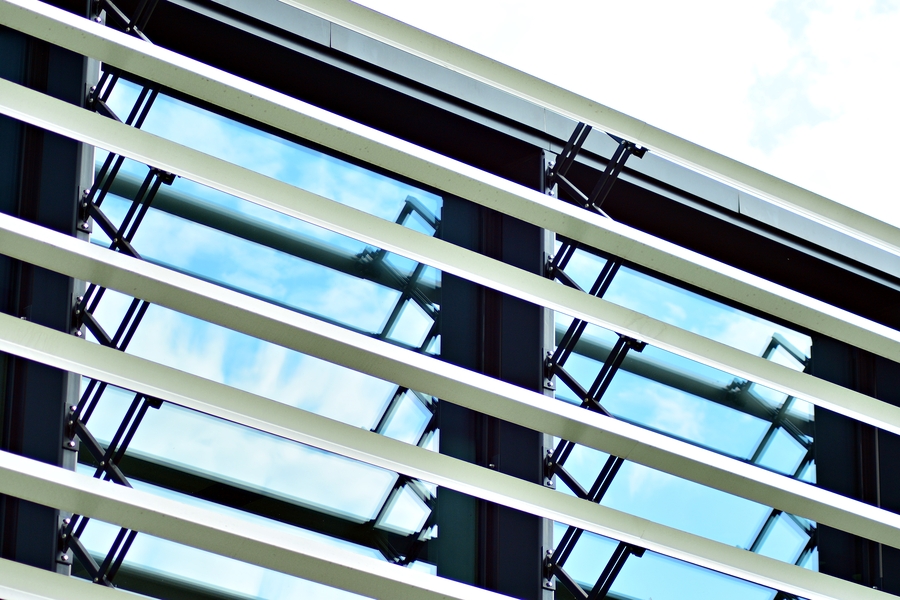

Industrial blinds

One of the best solutions for shed air conditioning is the installation of industrial blinds, because they allow constant ventilation, ensuring proper ventilation of the environment.

When acquired with a lantern, they also help in the exhaustion of gases and particles in suspension in the internal environment and avoid the exposure of workers to sudden changes in temperature.

They can be composed of PVC, polycarbonate, galvanised or aluminium fins, which are generally installed on the side walls of the warehouses, and can be fixed or mobile. In the case of the mobile ones, they may be manually or automatically operated.

The great advantage of industrial blinds is that they contribute to the energy efficiency of the shed, as they reduce the need for mechanical air-conditioning systems. Thus, the natural ventilation provided by industrial blinds is a more sustainable and economical solution.

In addition, translucent polycarbonate blinds, an option here from the MB group, allow natural light to enter and reduce the need for artificial lighting, contributing to the energy efficiency of the shed.

Finally, industrial blinds are also easy to install and require little maintenance, requiring only cleaning with a cloth or a water jet, in addition to being durable, self-extinguishing, and resistant to weathering and the action of time.

It is important to choose the right Venetian blind material for the size and characteristics of the shed, taking into account the air flow required to ensure adequate ventilation.

Natural Gravity Air Exhaust

Gravity natural air exhausters are elements installed on the roof of warehouses, which allow the renewal of the air in the environment. They are composed of openings in the highest parts of the shed.

The natural air exhausters by gravity are an interesting option for the climatization of warehouses, because they allow the natural exhaustion of the hot air accumulated in the upper part of the building. They work from the chimney effect, through the displacement of air caused by temperature and pressure differences between the internal and external environments of the factory.

When the openings of the natural air exhaust by gravity are combined with blinds, located on the sides of the sheds, it is possible to increase the number of air exchanges in the environment. This would be the venturi effect, which occurs from some air intake in the place, enhancing the physical effect, which accelerates this process of air output.

If the steel plates that make them up are made of polycarbonate (a possibility offered here by the MB Group), it is also possible to guarantee the entry of natural light in addition to air exchange. It is a type of 2 in 1 solution.

Forced ventilation

Forced ventilation is the use of fans, air conditioners and mechanical exhausts to move air around the house.

This solution is indicated in industrial activities that generate a lot of heat - however, there is a higher cost with energy, besides the respiratory problems due to the stale air in the place and the temperature shocks between the internal and external area

How to choose the ideal option

In general, the choice of HVAC solution should consider energy efficiency, implementation and operation costs, ease of maintenance, and suitability to the needs of the location and the activities performed.

After all, as we have seen, it is of utmost importance to adopt efficient solutions for air-conditioning industrial warehouses, because they reduce costs with electricity and equipment maintenance, in addition to ensuring more well-being to employees and, consequently, increased productivity.

On the other hand, poorly designed or sized systems can generate inefficiency in energy consumption.

In addition to these mentioned aspects, it is also important to consider sustainability when choosing an air conditioning solution for industrial warehouses.

Opting for sustainable solutions, such as natural ventilation options, contributes to the reduction of environmental impact and to the company's positive image before society and the market. Thus, in addition to bringing economic and welfare benefits to employees, the choice of sustainable solutions also brings advantages in terms of social and environmental responsibility.

In this context, it is important to have the advice of a professional specialized in air conditioning to make the most appropriate choice. The support of a professional will be useful for choosing the best ventilation solution in your case.

Options such as rooflights and industrial shutters, besides being more sustainable, contribute to the thermal comfort of the workers who work in these places, avoid health problems and, consequently, increase productivity.

The MB Group offers the best solutions in natural lighting and ventilation for industry. Contact us and find out how we can help!